Device for Concentrate Dilution and Dosing

Description of the Technology

Use of the equipment begins with selection of the product from offered products list, afterwards reusable bottle (13) must be placed under the chosen product dosing unit (9) and finally push-button (1) needs to be pressed to activate the dilution and dosing process. Upon receipt of the input signal from the start button the control unit forms an output signal which activates the actuators which ensure the flow of water through the dosing unit, thereby initiating the process of dilution and dosing. When the process is completed, the user removes the filled bottle from the device and tighten it.

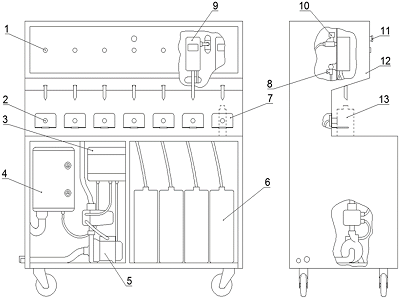

Main components of the device are shown in Fig. 1.

Fig. 1. Main components of the device.

- Push-button for starting the process (one for each product).

- Packaging sensor (one for each product).

- Electrical enclosure.

- Control unit.

- Centrifugal pump with a pressure regulation;

- Concentrate basin (one for each product);

- Packaging holder (one for each product);

- Water distribution unit;

- Dosing unit (one for each product);

- Solenoid valve (one for each product);

- Emergency STOP;

- Device frame;

- Reusable bottle.

Applications

The device can be used for any kind of liquid concentrate dilution with water and dosing in reusable bottle. Most suitable application for device is household chemical (various detergents and disinfectants) dilution and dosing, but it can be equally well used in food industry for various drink concentrate dilution with water etc. Device can be supplemented with more advanced control system that allows to monitor the maximum amount of product available for a particular user, which can be very useful in hotel networks to control necessary amount of cleanser for each housemaid.

Advantages

Since the product packaging (bottle) can be reused, it significantly reduces amount of used plastic bottles, which results in a positive impact on the environment, as well as reduced waste disposal and recycling-related expenditure. Extra financial benefit is achieved because the water that is needed to dilute the concentrate is taken directly at the location where device is located, thus allowing to transport only concentrate cans, which occupy significantly less space. When ordering device customer can individually determine the number of dosing units and product packaging size, thus adapting the equipment for each particular case. Device can be used for various types of liquids (beverages, household chemicals, etc.). Equipment can be complemented by control system that allows to monitor the amount of used products.

Keywords

concentrate dilution,consumption control,filling automation,resource saving,environmental protection